Nitrogen is an inert gas which is not very reactive with other elements and chemicals. Nitrogen is accounting for around 78% of the earth’s atmosphere which is highly abundant. Nitrogen gas has been used in laboratory analysis for example supply an LC-MS(Liquid Chromatography-Mass Spectrometer) instrument or a detector like Gas Chromatography for decades. Nitrogen gas supply were delivered in cylinders or in bottles from the closest nitrogen plant to the lab in the past, but it takes time to deliver. Nitrogen generation systems are the most efficient way to supply consistent high purity of instrument gas which will never runs out of gas like the traditional gas cylinders.

The on-site nitrogen generator is an alternative to the traditional nitrogen cylinders. The nitrogen generator provides consistent purity of nitrogen gas with an uninterrupted supply. And the Pressure Swing Adsorption(PSA) and membrane nitrogen generators are the two technologies which work behind the nitrogen generator.

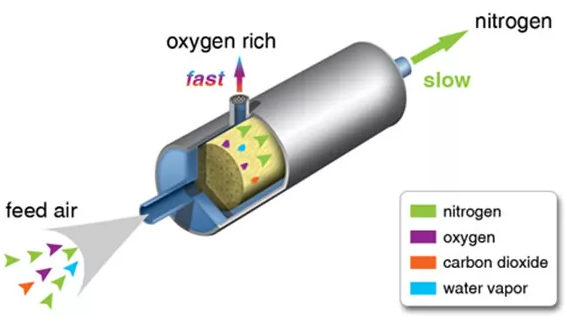

The atmospheric air passed through a hollow fiber membrane which is compressed by an air compressor in a membrane nitrogen generator. A high purity nitrogen gas is generated after filtering out the other part in air which is mainly oxygen. There are multiple stages of filtration in the nitrogen generation process before reaching the membrane. The fine mesh filters are commonly used for removing particles in air and also remove moisture by air dryers at the same time to protect the membrane.

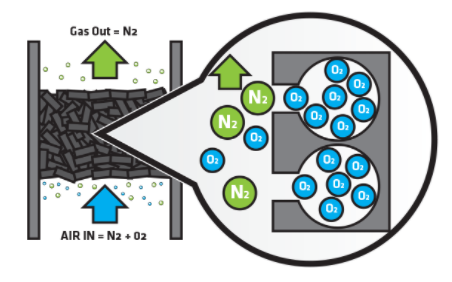

The other technology is a PSA nitrogen generator(Pressure Swing Adsorption). The PSA nitrogen generator works similar to the membrane nitrogen generator. The difference between the PSA nitrogen generator and membrane nitrogen generator is that the air will pass through a column of tightly packed material at a pressure made of carbon called a Carbon Molecular Sieve(CMS) instead of passing through a membrane. The principle of the CMS is adsorbing larger molecules of oxygen and other molecules and allowing the smaller nitrogen molecules to pass through and this result in leaving high purity nitrogen. A PSA nitrogen generator included two CMS columns which one of them push the air through the sieve at pressure and the other one is decrease the pressure.

The features of Domnick Hunter LCMS 30-1-E Generator:

• High purity, organic free nitrogen

• Produces a continuous supply of LC/MS grade nitrogen 24/7

• Integral oil free compressors

• Optional ECOMax economy module to increase compressor life

• Compact, reliable with minimal operator attention and maintenance

• Phthalate-free componentry

Leave a Comment